Engraving items with a laser-based system at home is amazingly convenient for one-off parts, but what happens when the production volume needs to increase? For element14 Presents host Clem Mayer, this usually meant preparing many uniform pieces of engraving stock, opening the laser’s enclosure, placing down the material, and then finally running the machine. In doing so, the process could introduce errors and was simply inefficient, leading Mayer to think of a way to automate things instead.

The limiting factor was mostly about how long it took to change the material, so Mayer got to work designing a carousel-like device that could house up to four sheets of stock and rotate each one into place after the previous one had finished. A stepper motor driven by a Trinamic TMC2100 was responsible for moving the drum while an Arduino UNO Rev3 received inputs from external switches and then sent pulses to the motor driver accordingly.

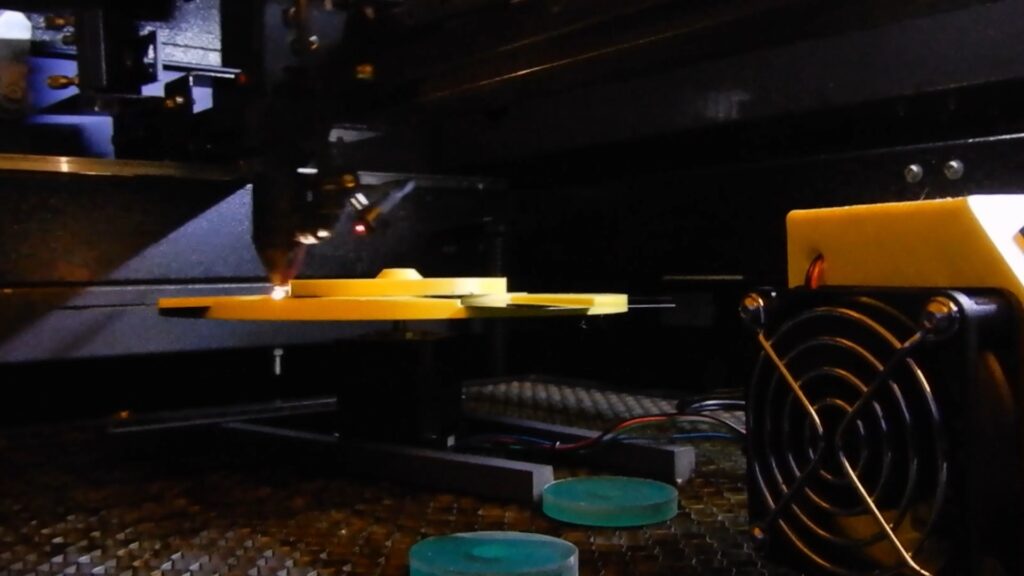

Once placed into the laser cutter’s enclosure, Mayer quickly discovered that his vertical drum design was too tall and interfered with the toolhead. This necessitated swapping the orientation to a flat disc where material could be positioned around a spinning turn table. The original spring-loaded clamps were also exchanged for a magnetic system that is strong yet easily removable.

To see more about this project, you can watch Mayer’s build log video below!

The post Improve laser engraving speeds with an Arduino-controlled turntable appeared first on Arduino Blog.