An affordable, AI-assisted, wearable robotic arm? That’s not science fiction – it’s RedSnapper, an open-source prosthesis built by PAC Tech, a team of high school students from Istituto Maria Immacolata in Gorgonzola, Italy. Powered entirely by Arduino boards, their project won the national “Robot Arm Makers” title at the 2025 RomeCup – and we think it’s a perfect example of what young minds can do with passion, creativity, and technology.

A smart, affordable prosthetic – made with Arduino

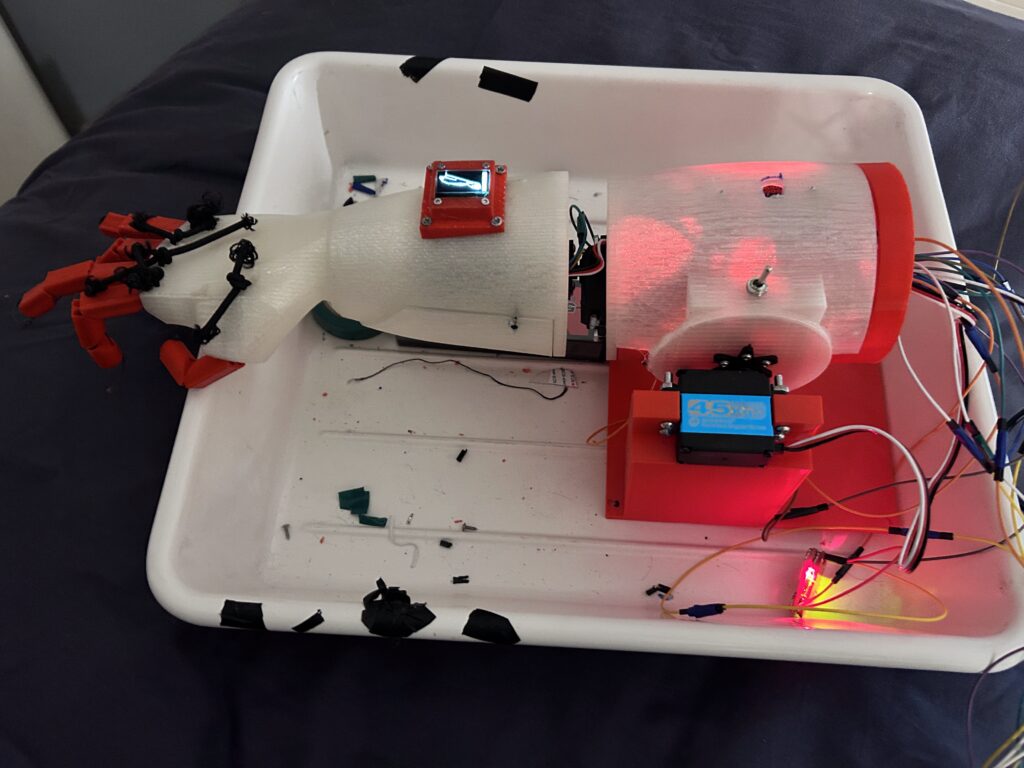

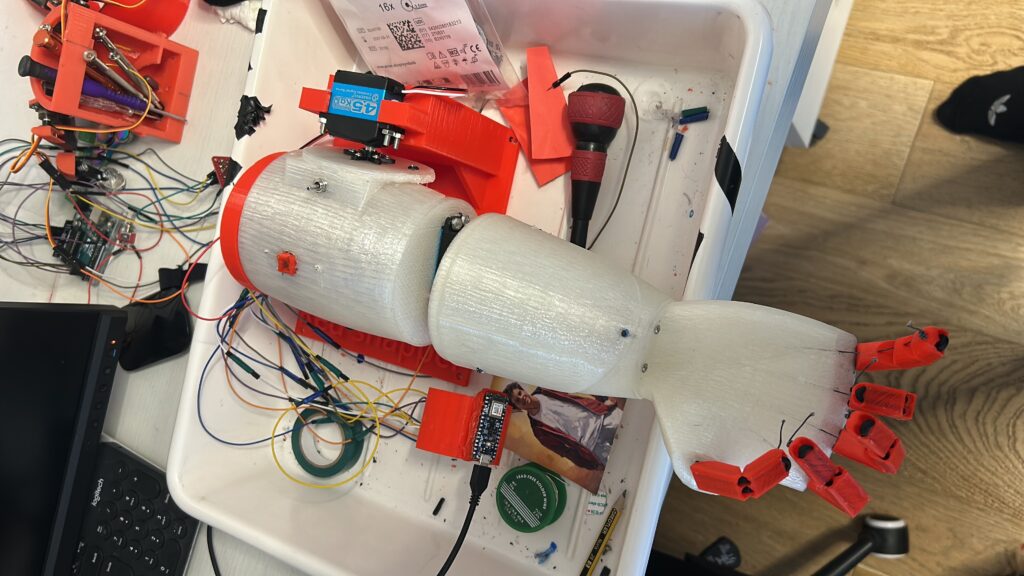

RedSnapper is a 3D-printed, EMG-controlled robotic arm that combines AI, embedded systems, and real-time feedback – all compacted into a lightweight, wearable form. Its brain? An Arduino Nano 33 BLE Sense.

The prosthetic is capable of performing complex and natural movements by combining voice control, tinyML models, muscle signals, and motion detection from the Nano 33 BLE Sense’s onboard sensors. It also includes temperature and force sensors on the palm to alert the user when things get too hot or too tight.

The best part? All components are open source and budget-friendly. The total cost of the arm is just around 400 euro, making it a potentially life-changing solution for people who might not otherwise have access to a functional and good-looking prosthesis. “We designed RedSnapper to be powerful, but accessible. Something that could actually make a difference,” says Mattia Arnaldi, who led the software and electronics design for the project.

Daniele Vallicelli, Francesco Colombo, and Mattia Arnaldi (L to R) are PAC Tech, the team behind RedSnapper.

Making AI run on Arduino

PAC Tech’s custom assistant, called JARVIS (Just A Rather Very Intelligent System), allows the user to control RedSnapper with voice commands like “raise arm” or “rotate wrist.” To get JARVIS working on the Nano 33 BLE Sense, Arnaldi trained the models using Edge Impulse. “I collected around 120 samples per keyword and ran performance calibration to choose the best algorithm cluster. That helped us find the most accurate and efficient model for our use case,” he explains

With an update rate of 200 ms, the resulting movements are smooth, responsive, and tailored to the user’s input – whether that’s from voice, muscle contraction, or gestures.

Challenges? Plenty. Solutions? Creative.

As with any ambitious prototype, the team ran into real-world problems. Powering three high-torque servos, sensors, and microcontrollers with jumper wires wasn’t working: the system needed a stable, high-current setup. Their fix was to replace all jumpers with XT60 connectors for maximum reliability.

“We also had trouble stabilizing elbow movement,” Arnaldi adds. “We solved it by redesigning the joint and adding a second support with a bearing. That small change made everything more efficient.”

Funding was another hurdle. Between parts and prototypes, costs reached 1,000 euro – quite a challenge for a group of high schoolers. Thanks to support from their school, a crowdfunding campaign, and their own savings, they made it happen.

Learning by doing (and rebuilding)

This was more than a school project. For Arnaldi, Vallicelli, and Colombo it was a full learning experience. From 3D modeling and circuit design to AI training and team collaboration, they gained hands-on skills that can’t be taught by textbooks alone.

RedSnapper’s strength lies in its modularity and ambition: it’s a device designed for real use, yet developed by teenagers. That’s something worth celebrating.

Follow their journey – and share yours too!

Want to know more about PAC Tech and RedSnapper? Visit their website at pactech.mystrikingly.com and follow them on Instagram at @pac_tech_.

And if you’re building something exciting with Arduino – whether it’s a robotic arm or your very first project – we’d love to see it! Share your work with the community on Project Hub and help inspire the next wave of makers.

The post Meet the teens behind RedSnapper: a smart Arduino-powered prosthetic arm appeared first on Arduino Blog.